Máquina de produção de grânulos de reciclagem de plástico fácil de operar

Descrição

Informação básica

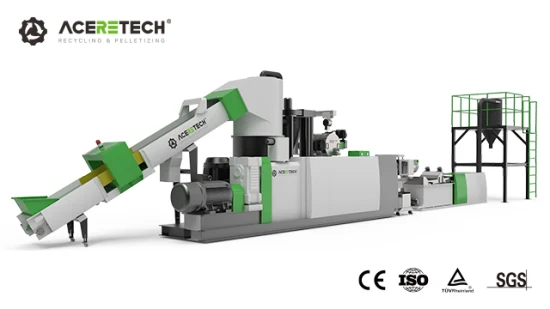

| Modelo Nº. | ACS-PRO |

| Parafuso | Parafuso Único |

| Inversor | Inversor |

| Aquecedor eletromagnético | Aquecedor de cerâmica ou aquecedor de infravermelho distante |

| Automação | Automático |

| computadorizado | computadorizado |

| Personalizado | Personalizado |

| Certificação | CE, ISO9001:2008 |

| Doença | Novo |

| Tipo de máquina | Máquina de Reciclagem |

| Tensão | 380V 50Hz ou Personalizado |

| Componentes Elétricos | ABB, Ls, Omron ou Personalizado |

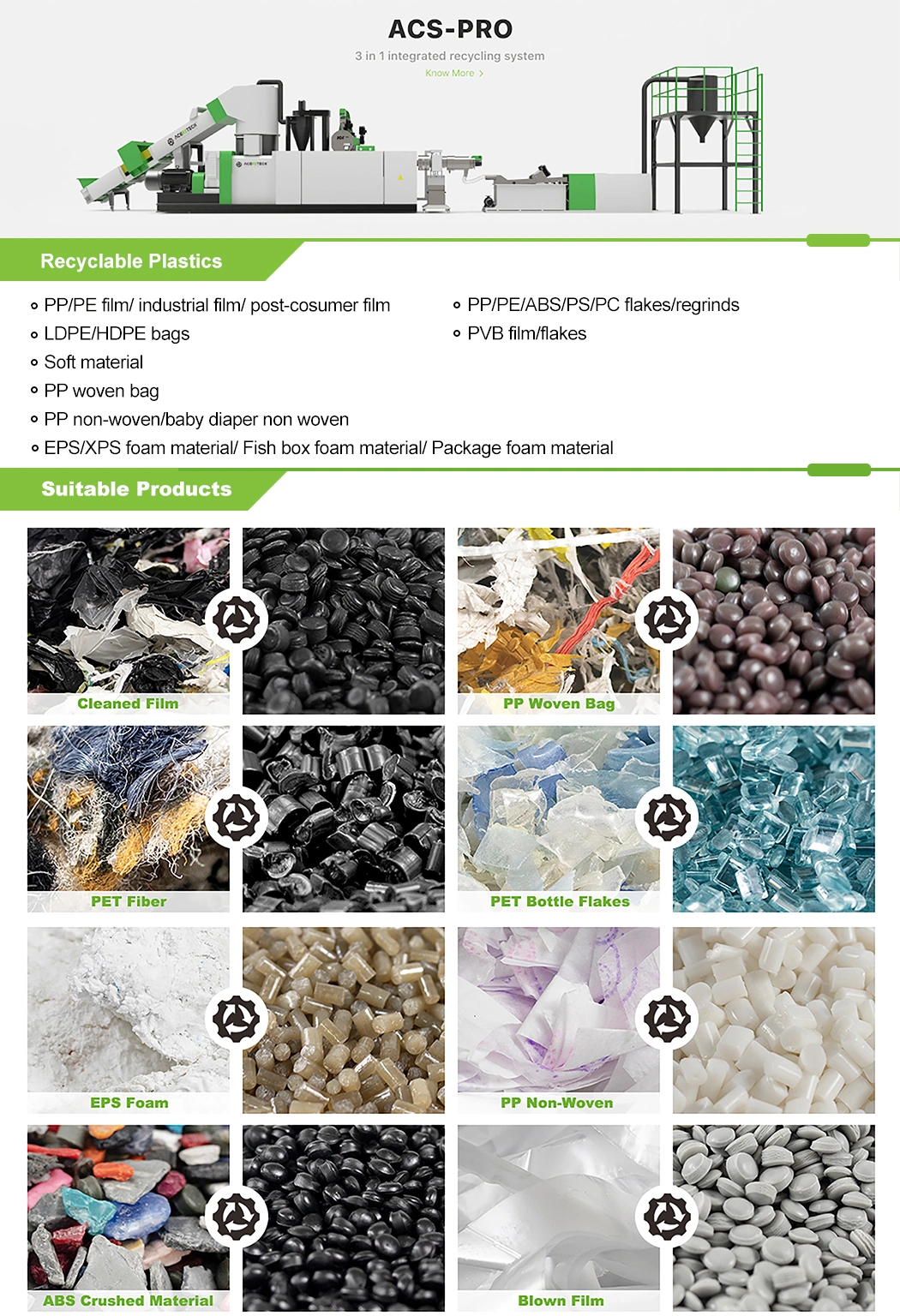

| Aplicativo | Filme, Filamento, Ráfia, Espuma |

| Tamanho da sala de compactação | 800L-2800L |

| Faixa de capacidade | 320kg/A-2100kg/A |

| Alvo sendo material reciclado | PP PE Pet ABS PS PC |

| Ao controle | Controle CLP |

| Amostra/manual de serviço | Disponível |

| Localização da Fábrica | 2 horas de carro de Xangai |

| Serviço pós-venda | Peças sobressalentes gratuitas |

| Produto final | Pelotas/Grânulos |

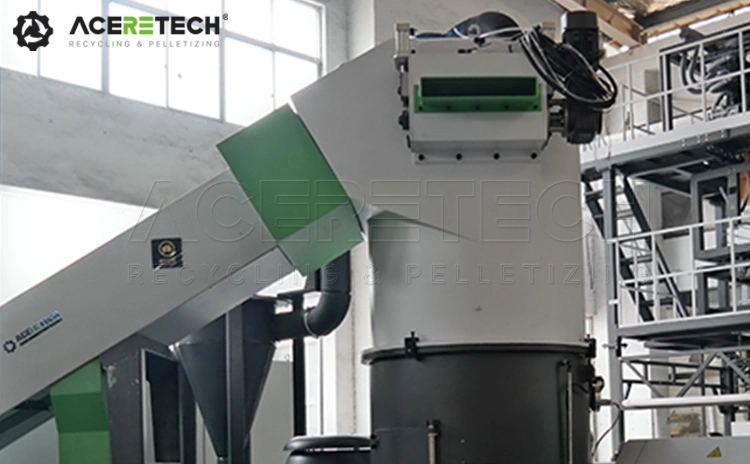

>> Multiple selection of smart feeding method: Plastic scraps can choose belt conveyor; Rolls' scraps can choose roll hauling off device;Feeding speed is automatically.>>> Strong crushing and compacting unit:Rotatory blades of compactor will cut up incoming scraps;Frictional heating will dry and compacts the materials;Feed from the compactor directly into the extruder.Sliding gate make it can handle both film and rigid scraps.p>

>> Multiple selection of smart feeding method: Plastic scraps can choose belt conveyor; Rolls' scraps can choose roll hauling off device;Feeding speed is automatically.>>> Strong crushing and compacting unit:Rotatory blades of compactor will cut up incoming scraps;Frictional heating will dry and compacts the materials;Feed from the compactor directly into the extruder.Sliding gate make it can handle both film and rigid scraps.p> >> Specialized single screw extruder: Equipped with high torque gearbox with integrated design; 50D processing section to gently melt the plastics;Bi-metal Screws and barrels ensure 2 times use life than usual..>>> Double-zone vacuum degassing systemDouble-zone degassing can remove the volatiles efficiency;Equipped with vacuum tank, which store the impurities, small molecules or oil stains from the exhaust.p>

>> Specialized single screw extruder: Equipped with high torque gearbox with integrated design; 50D processing section to gently melt the plastics;Bi-metal Screws and barrels ensure 2 times use life than usual..>>> Double-zone vacuum degassing systemDouble-zone degassing can remove the volatiles efficiency;Equipped with vacuum tank, which store the impurities, small molecules or oil stains from the exhaust.p> >> Plate type double station filter: Cost - effective,Easy to operate;>>> Piston type large area filter:Suitable for heavy contaminated materialSuitable for large capacity recycling machine;>>> SCF type Self-clean filterNo need to change the mesh screen;Automatically discharge the impurities;Can realize 60mesh, 80mesh 100mesh and 120mesh.p>

>> Plate type double station filter: Cost - effective,Easy to operate;>>> Piston type large area filter:Suitable for heavy contaminated materialSuitable for large capacity recycling machine;>>> SCF type Self-clean filterNo need to change the mesh screen;Automatically discharge the impurities;Can realize 60mesh, 80mesh 100mesh and 120mesh.p> >> For different materials and different usage scenarios, we can provide you different pelletizing systems. Water-ring pelletizing system: Standard granulating method in ACS-H system; Self-adjusting pelletizing head ;RPM of rotatory blades is automatic.Pelletizing System>>> Under-water pelletizing system:Suitable for big capacity, automatically,Applicable to a wider range of materials.Pelletizing System>>> Water-strands pelletizing system:Cost-effective;Suitable for the material which MFI is higher than 8.Drying & Packing System>>> Vibration: Sieve is made of Stainless steel ; Dewatering granules and selecting size.Centrifugal dryer:Horizontal-type which is lower energy consumption;Blower on the dryer to remove the moisture further;Equipped with sound-proofing cover to reduce noise.Product silo:All pipes and silos wrapped with sound -proofing cotton;Optional Capacity online monitoring & Quantitative weighing. Intelligence Operating>>> Intelligence Start: One button only.>>> Intelligence Stop: One button only.>>> Emergency Stop: One button only.Remote monitoring and information transmission.br>

>> For different materials and different usage scenarios, we can provide you different pelletizing systems. Water-ring pelletizing system: Standard granulating method in ACS-H system; Self-adjusting pelletizing head ;RPM of rotatory blades is automatic.Pelletizing System>>> Under-water pelletizing system:Suitable for big capacity, automatically,Applicable to a wider range of materials.Pelletizing System>>> Water-strands pelletizing system:Cost-effective;Suitable for the material which MFI is higher than 8.Drying & Packing System>>> Vibration: Sieve is made of Stainless steel ; Dewatering granules and selecting size.Centrifugal dryer:Horizontal-type which is lower energy consumption;Blower on the dryer to remove the moisture further;Equipped with sound-proofing cover to reduce noise.Product silo:All pipes and silos wrapped with sound -proofing cotton;Optional Capacity online monitoring & Quantitative weighing. Intelligence Operating>>> Intelligence Start: One button only.>>> Intelligence Stop: One button only.>>> Emergency Stop: One button only.Remote monitoring and information transmission.br>

Nosso contato